MODEL: ABSL-120

The bottles travelling through conveyor are held for some distance by roller separators and back up guide are passed to the labelling station in an upright position. When the Bottle reach to the labelling station, the sensor operates the servo motor. At this point of time, the sticker touches the Bottle and wrapped over the Bottle by the driven belt on roller. Then Rubber belts press the Labels on Bottle during passing through Rubber belt. The labelled Bottle pushed to unloading tray.

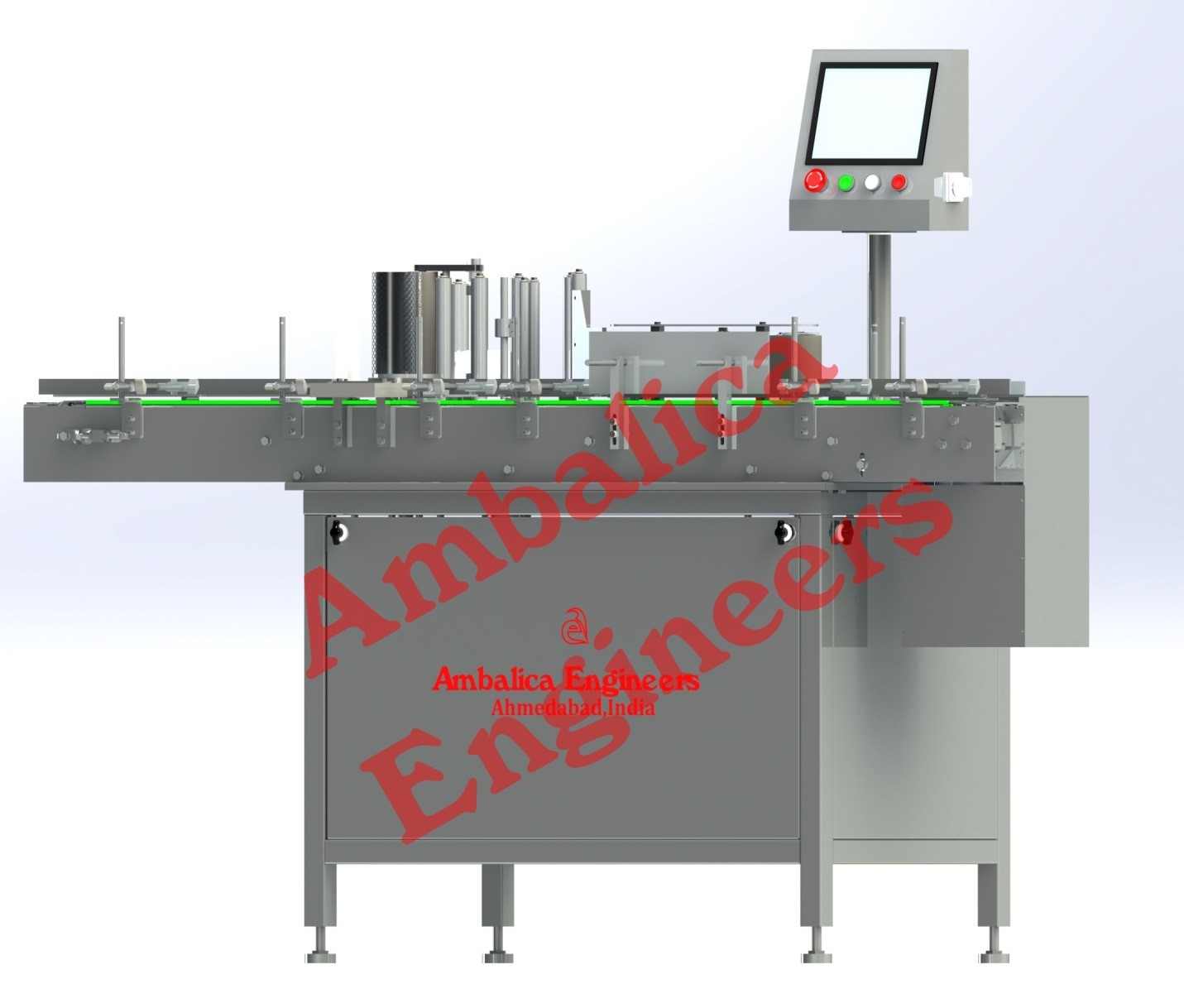

MODEL: ABDSL-120

The containers travelling through conveyor are held for some distance by roller separators and back up guide are passed to the labelling station in an upright position. When the Bottle reach to the labelling station, the sensor operates the servo motor. At this point of time, the sticker touches the Bottle and stick on the front/back surface of Bottle by the driven belt on roller. Then Rubber belts press the Labels on Bottle during passing through Rubber belt. The labelled Bottle pushed to unloading tray.

MODEL: ABSL-120

|

Machine Model |

ABSL-120 |

|

|

Output/Minute |

60-120 Bottles |

|

|

Working direction |

Left to Right |

|

|

Electric Characteristic |

2.5 HP/230V/1440 RPM/Single Phase/50 Hz |

|

|

Power Supply |

Single Phase/3 Phase, 4 Wire |

|

|

Input Specifications |

Bottle dia. |

22mm to 70mm |

|

Label size |

10mm to 200mm |

|

|

Overall dimensions |

1800mm L x 1150mm W x 1500mm H |

|

|

Net Weight |

250 kgs. |

|

|

Gross Weight |

550 kgs. |

|

MODEL: ABDSL-120

|

Machine Model |

ABDSL-120 |

|

|

Output/Minute |

60-120 Bottles |

|

|

Working direction |

Left to Right |

|

|

Electric Characteristic |

1 HP/230V/1440 RPM/Single Phase/50 Hz |

|

|

Power Supply |

Single Phase/3 Phase, 4 Wire |

|

|

Input Specifications |

Bottle dia. |

22mm to 70mm |

|

Label size |

10mm to 200mm |

|

|

Overall dimensions |

3000mm L x 2350mm W x 1500mm H |

|

|

Net Weight |

450 kgs. |

|

|

Gross Weight |

800 kgs. |

|